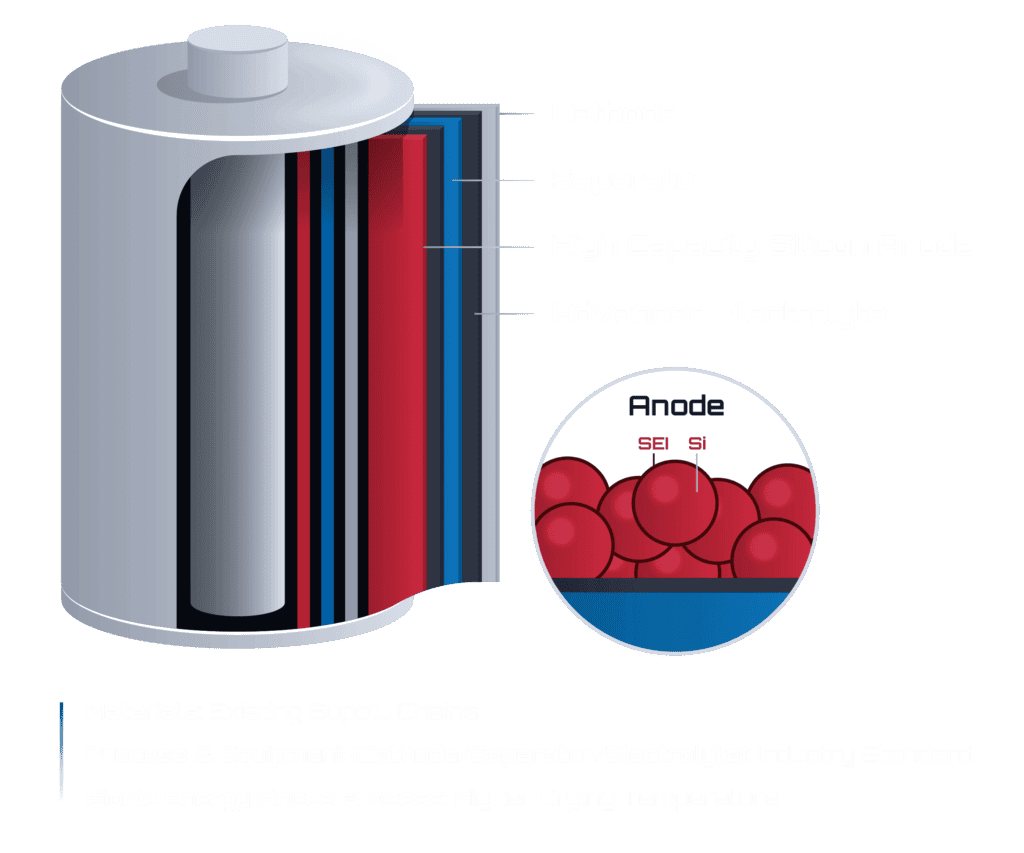

Group14 silicon anodes in lithium ion batteres are providing a 40% improvement for energy density, charging speed and lifecycles. The relentless pursuit of improved battery performance drives rapid advancements in energy storage technology. Nano silicon anodes for lithium-ion batteries [1], [2] [3] [4] have been in development for more than a decade. Other companies such as Sila have developed Silicon anodes and battery companies are not doubt researching themselves, but Group14 appears to have developed a sustainable lead.

For over a decade, researchers knew silicon could significantly enhance battery capacity, with a theoretical specific capacity nearly ten times higher than that of the currently dominant graphite anode. Advantages of silicon anode include

- Superior lithium-ion storage capacity compared to its bulk counterpart. It is due to increased surface area and shorter lithium-ion diffusion paths.

- Faster charging down to 7C (1 C is one hour, so 7 C is 9 minutes.

- Long life – higher number of charge and discharge cycles. Targeting over 1,000 cycles.

Group14 Silicon Anodes for Batteries

In 2023, Sila Sechnologies reported promising outcomes. They have moved to production. Group14 show major advancements and progress and Group14 has now surpassed Sila Nanotechnologies and is rapidly scaling up production with multiple factories planned.

Group14’s marketing challenge is not with manufacturers. Manufacturers are already evaluating their product and trying to make their own product in house. However, Group14 lack public endorsements from EV makers. As in most industries “not invented here” syndrome is a alive and well.

First Use In Mobile Phones

As is usually the case, new battery innovation starts in consumer electronics, moves to EVs and ultimately to BESS application. Silicon anodes are no different. What phone consumers want is increased battery life. As phones get AI, more memory and 200MP cameras, consumer demand not just 24 hour life but days of life. Check out battery capacity. What used to be 4000mAh (4Ah) devices have now risen to 8Ah batteries. This extends life by 40%, critical for AI-based applications.

The technology has flooded the smartphone market in China. Two years ago, there were no silicon carbon batteries in smartphones. Today, you essentially won’t see a new smartphone announced without a silicon-carbon battery featured in the specs. [6] This advertisement in India shows SiC batteries in OnePlus, Vivo (Oppo), Honor (ex Huwai) and Xiaomi – the 3 largest Chinese manufacturers. TDK has announced they are ramping production 2025, which is a leading indicator for adoption by Apple and Samsung. Samsung does not have SiC in their S25, but their S26 almost certainly will.

When a $US350 smartphone, (Poco X7 Pro) has a 6,550mAh silicon carbon battery, you know the technology is main stream.

That change in mobile phones is likely to extend to EVs with increased density and faster (7C) charging with extended life.

Group14 Company Activities

Group14 Technologies began commercial production in 2021 from its 120 tonne pilot plant in Woodinville, WA. [5] Group14 claims this has enabled all top battery makers and EV OEMs to be in evaluation and qualification for years. Group14 lead the others producing this new technology at scale. Will others catch up? Maybe not.

Large Scale Production

Silicon anodes are a compelling improvement. Large-scale commercial manufacturing capability has been proven. The first EV-scale anode plant in the world was commissioned in September (2,000 tonnes pa, 10 GWh) in Sangju, Korea. (JV with SK) [6] .

Group14 also have 2 more same-sized modules (4,000 tonnes, 20 GWh) are due to turn on in 2025 in Moses Lake, WA – on a site already permitted for six (12,000 tonnes, 60 GWh): YouTube video.

They claim this manufacturing capacity is larger than the combination of what all others are forecasted to have in this time frame.

Nano Silicon Anode Use in EVs

As batteries find their use in consumer devices, they move into EVs and other battery uses. Molicel’s P50B in Q3 2024: [7]

- Similar life cycle range to iron-phosphate batteries

- Double the power density

- Half the charge times of the best cylindrical lithium-ion batteries on the market today

Molicel is a larger Taiwanese company making batteries for many OEM manufacturers for use in motor vehicles and motorcycles. Their latest battery INR-21700-P50B is a 21700 style battery, 3.6V with a typical capacity of 5.0Ah, 18Wh and an Energy Density of 714 Wh/l or 265 Wh/kg with a discharge current of 60A. When you consider batteries in the latest Tesla of 4680 made in Austin Texas are about 200Wh/kg – you can see that a 33% increase in battery means extended range, with lower weight and longer battery life.

These higher capacity batteries will have use in high-end applications that demand density.

- Racing Cars , The FASTEST Car You CAN BUY! McMurtry Speirling Pure BREAKS RECORDS

- Airplanes from Archer Archer commercializes air taxis in Abu Dhabi – electrive.com

- Drones Skylift Delivered over 5 Tons of Wind Turbine Equipment Offshore Using FlyingBasket Heavy lift Drones.

- IOT and Consumer devices [8]

- Consumer and mobility devices with production cells at 340 Wh/kg [9]

- Sionic is claiming the strongest performance of any silicon battery yet. That includes specific energy of at least 330 watt-hours per kilogram, a volumetric density of at least 842 watt-hours per liter, and a proven range of up to 1,200 cycles in 4 to 10 ampere-hour cell formats. [10]

- Storedot production-ready, long-range EV batteries can charge in 10 minutes. [11]

Group14 Increasing Commercialisation

No other silicon anode material supplier has this kind of third-party battery maker acceptance and traction. The result has been over $600M of “take or pay” contracts signed for the material. More are coming, as getting an increase of 30% of battery density is a significant cost advantage. Group 14 has over 30GWh of orders. [13] Many of them are with companies targeting high value, high performance battery markets. [14]

The global demand for batteries far exceeds the production capacity of Group 14 or other silicon anode providers and they will continue to use existing technology.

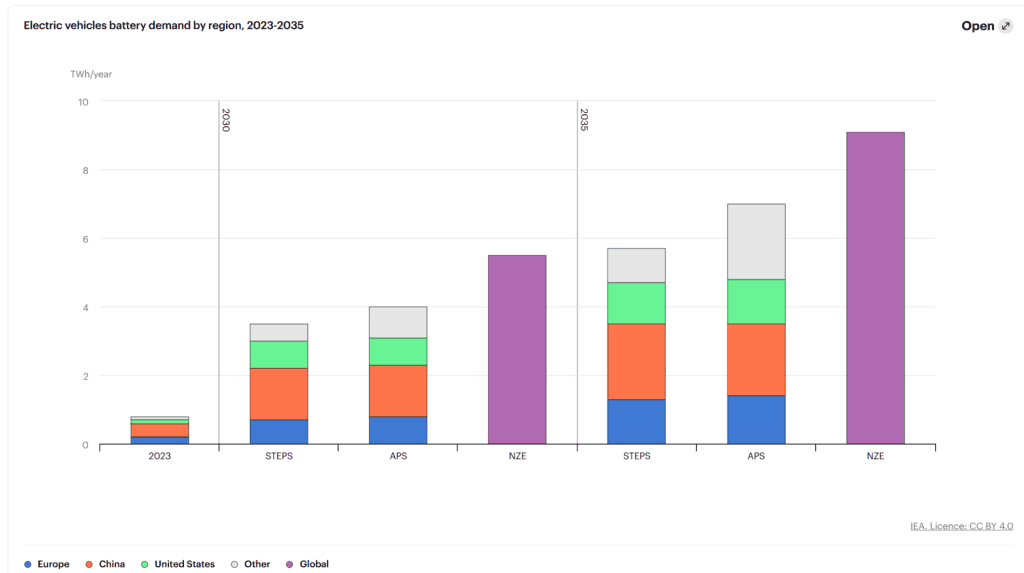

IEA predicts stationary storage will increase battery demand to over 500 GWh by 2030, which is about 12% of EV battery demand. [15]

Will Tesla Use Silicon Anodes?

An unnamed source in a report in October 2024 [16] claimed Tesla aims to produce between 2,000 and 3,000 Cybertrucks per week using dry-cathode (4680D) cells for 100,000 to 150,000 vehicles. Tesla had said they would be able to produce 250,000 Cybertrucks per year but in late 2024, Tesla was run rate was 75,000 per year. Most expect them to double that in 2025. This means a doubling of current production using regular (second-generation) 4680 cells, also known as “Cybercells.” By 2026, Tesla will expand its dry-cathode 4680 cell lineup with four new variants. These are named internally NC05, NC20, NC30, and NC50, respectively, with NC standing for “new cell.”

Expansion of Silicon to all LiOn Production

Group14 claims their material is a drop-in to the billions of dollars of Li-ion capacity all around the world – so adoption is straightforward now that manufacturing capacity exists (at least from Group14). However, as we say in battery manufacturing, batteries are part science, part art form.

Battery Demand Increasing

The renewable energy transition to the Energy Era 4 of is less than 10% through. Demand for batteries will continue to expand. We know incumbent consulting companies have consistently underestimated the demand for solar, wind, batteries and EVs.

The electricity demand with AI datacenters will double over the next 5 years. Currently data centers consume about 5% of the total electricity in the USA. Prices are expected to fall, based on Wrights Law.

Battery manufacturers are in a prime spot to capitalise on battery demand.

Conclusion

Solid-state batteries continue to dazzle the imagination. Sodium batteries will ultimately provide cheaper batteries. Lithium sulfur provide higher density. But silicon anode batteries are here today. They appear to provide sufficient performance improvements that others are just promising. And other enhancements will see that improvement double or triple over the next decade.

References

[1] ‘A Brief Overview of Silicon Nanoparticles as Anode Material: A Transition from Lithium‐Ion to Sodium‐Ion Batteries – Fereydooni – 2024 – Small – Wiley Online Library’. Accessed: Jan. 24, 2025. [Online]. Available: https://onlinelibrary.wiley.com/doi/10.1002/smll.202307275

[2] SiO2-Based Lithium-Ion Battery Anode Materials: A Brief Review’. Accessed: Jan. 24, 2025. [Online]. Available: https://www.researchgate.net/publication/360270347_SiO2-Based_Lithium-Ion_Battery_Anode_Materials_A_Brief_Review

[3] D. M. Piper et al., ‘Stable silicon-ionic liquid interface for next-generation lithium-ion batteries’, Nat. Commun., vol. 6, no. 1, p. 6230, Feb. 2015, doi: 10.1038/ncomms7230.

[4] ‘Recent progress and challenges in silicon-based anode materials for lithium-ion batteries – Industrial Chemistry & Materials (RSC Publishing) DOI:10.1039/D3IM00115F’. Accessed: Jan. 24, 2025. [Online]. Available: https://pubs.rsc.org/en/content/articlehtml/2024/im/d3im00115f

[5] ‘Silicon for batteries moves to commercial production – pv magazine International’. Accessed: Jan. 24, 2025. [Online]. Available: https://www.pv-magazine.com/2021/04/13/silicon-for-batteries-moves-to-commercial-production/

[6] ‘Group14 Delivers SCC55TM to Over 100 Customers Worldwide’, Group14. Accessed: Jan. 24, 2025. [Online]. Available: https://group14.technology/resources/press-releases/group14-delivers-scc55-to-over-100-customers-worldwide/

[7] ‘Group14’s Silicon Battery Material Enables Breakthrough Power and Charging Performance’, Group14. Accessed: Jan. 24, 2025. [Online]. Available: https://group14.technology/resources/press-releases/group14s-silicon-battery-material-enables-breakthrough-power-and-charging-performance/

[8] ‘Enovix and Group14 Announce Collaboration to Develop Best-in-Class Silicon Batteries | Enovix’. Accessed: Jan. 24, 2025. [Online]. Available: https://ir.enovix.com/news-releases/news-release-details/enovix-and-group14-announce-collaboration-develop-best-class/

[9] Tests confirm InoBat’s 31Ah Battery Offers a Groundbreaking Solution for the high-performance mobility markets’, InoBat. Accessed: Jan. 24, 2025. [Online]. Available: https://www.inobat.eu/newsroom/tests-confirm-inobats-31ah-battery-offers-a-groundbreaking-solution-for-the-high-performance-mobility-markets/

Even More Reading!

[10] ‘Battery Tech Silicon battery technology’, Sionic Energy. Accessed: Jan. 24, 2025. [Online]. Available: https://sionicenergy.com/lithium-ion-battery-technology

[11] StoreDot, ‘StoreDot’s EV Battery Customization Takes Off: 5 Major Automakers On Board’. Accessed: Jan. 24, 2025. [Online]. Available: https://www.prnewswire.com/il/news-releases/storedots-ev-battery-customization-takes-off-5-major-automakers-on-board-302270023.html

[12] ‘Silicon Anode Batteries for EVs Are Ready for Production – IEEE Spectrum’. Accessed: Jan. 24, 2025. [Online]. Available: https://spectrum.ieee.org/silicon-anode-battery-2670396855

[13] G. Technologies, ‘Group14 Signs Agreements with Five Leading EV and CE Cell Manufacturers Supporting Global Electrification Efforts’. Accessed: Jan. 24, 2025. [Online]. Available: https://www.prnewswire.com/news-releases/group14-signs-agreements-with-five-leading-ev-and-ce-cell-manufacturers-supporting-global-electrification-efforts-302162657.html

[14] ‘Group14 and CustomCells Sign a Multi-Year Supply Agreement for SCC55TM’, Group14. Accessed: Jan. 24, 2025. [Online]. Available: https://group14.technology/resources/press-releases/group14-and-customcells-sign-a-multi-year-supply-agreement-for-scc55/

[15] ‘Outlook for battery and energy demand – Global EV Outlook 2024 – Analysis – IEA’. Accessed: Jan. 24, 2025. [Online]. Available: https://www.iea.org/reports/global-ev-outlook-2024/outlook-for-battery-and-energy-demand

[16] Tesla Reportedly Planning Four New Variants of Their Dry Cathode 4680 Batteries for 2026 – autoevolution’. Accessed: Jan. 24, 2025. [Online]. Available: https://www.autoevolution.com/news/tesla-reportedly-plans-four-new-variants-of-their-dry-cathode-4680-batteries-for-2026-240848.html