Industrial-scale bioplastic production is being implemented in select regions globally, primarily for applications like packaging, as documented by case studies such as a Malaysian palm biomass biorefinery (20,000 tons/year [1]) and Thailand’s cassava-based PLA and bioplastic bag production [2] [3], demonstrating localized cost and environmental advantages, but broader adoption is limited by high costs, scalability challenges, and performance trade-offs [4] [5].

1. Real-World Industrial-Scale Case Studies:

- Malaysia (P(3HB) from Palm Biomass): A biorefinery utilizing non-food oil palm fronds produces 20,000 tons/year of P(3HB) at 41% lower costs compared to commercial glucose feedstocks, demonstrating cost-effective industrial operations, though detailed deployment as conventional plastic replacement is limited [1].

- Thailand (Cassava to PLA/Market Adoption): Cassava-based PLA production demonstrated competitive economics under specific scenarios, with cost-benefit analysis showing net positive benefits under carbon trading schemes [2]. Thailand is also piloting bioplastic bags with a potential 10% market penetration [3].

- Global Examples (PHA Deployment): Companies like EarthFirst Films produce PHA for industrial packaging films, with real-world commercialization agreements exemplified by brands like Ikea integrating bioplastics [4].

2. Production Feasibility and Challenges:

- Feedstock Sourcing: Non-food biomass, such as oil palm residues [1] and cassava starch [2], offers localized cost advantages but faces scalability and competition trade-offs against food crops [5] [6] .

- Cost Barriers: Industrial production costs remain high (e.g., $3.44/kg for P(3HB) [1], creating challenges compared to fossil-based plastics despite localized successes.

- Technological and Process Optimization: Advances in microbial engineering and biorefining mitigate costs [7] [5] but large-scale adoption replacing petroleum-based plastics remains sporadic.

3. Primary Application Areas and Market Viability:

- Packaging Sector: Leading substitution potential seen in rigid (PLA) and biodegradable flexible applications (PHA), with examples of marine-biodegradable packaging made from PHAs being commercially deployed [4] [8]

- Market Integration Gaps: Despite promising localized adoption [2], [3], high costs and limited industrial performance in thermal stability and durability restrict expansion into sectors dominated by PE or PET-based plastics [5], [9].

4. Environmental & Lifecycle Considerations:

- LCA Insights: PLA and PHA outperform fossil-based plastics in lifecycle GHG emissions, particularly in regions like Thailand, but trade-offs include higher eutrophication potential due to agricultural runoff [5], [10]

- End-of-Life Challenges: Issues with compostability and contamination in recycling streams limit their full integration into circular economy frameworks [5], [9]

5. Role of Policy and Subsidies:

Policy incentives (e.g., carbon credits in Thailand, bio-economy strategies in Asia) play a critical role in localized successes but are necessary globally to overcome persistent economic barriers [2], [11], [12]

Conclusion – Industrial-Scale BioPlastic Production

Plastics are cheap and plentiful and the primary producers including Saudi Arabia, Russia and Iran do not want to change. 170 countries may wish to decrease plastic but they cannot come to any agreement. [13]

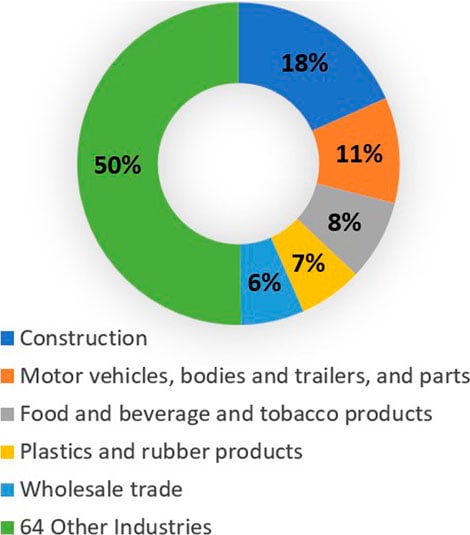

The uses of plastic are diverse. Over 64 industries make up half of use. Food is less than 8%.

References

[1] M. A. K. Zahari, H. Ariffin, M. Mokhtar, J. Salihon, Y. Shirai, and M. Hassan, ‘Case study for a palm biomass biorefinery utilizing renewable non-food sugars from oil palm frond for the production of poly(3-hydroxybutyrate) bioplastic’, J. Clean. Prod., vol. 87, pp. 284–290, 2015, https://doi:10.1016/J.JCLEPRO.2014.10.010.

[2] S. Chiarakorn, Chompoonuh K. Permpoonwiwat, and P. Nanthachatchavankul, ‘COST BENEFIT ANALYSIS OF BIOPLASTIC PRODUCTION IN THAILAND’, vol. 3, pp. 56–85, 2012.

[3] Narissara Kaewphan and S. Gheewala, ‘Greenhouse Gas Evaluation and Market Opportunity of Bioplastic Bags from Cassava in Thailand’, J. Sustain. Energy Environ., vol. 4, pp. 15–19, 2013.

[4] A. Costa, Telma Encarnação, R. Tavares, Tiago Todo Bom, and A. Mateus, ‘Bioplastics: Innovation for Green Transition’, Polymers, vol. 15, 2023, https://doi:10.3390/polym15030517.

[5] Kunnika Changwichan, T. Silalertruksa, and S. Gheewala, ‘Eco-Efficiency Assessment of Bioplastics Production Systems and End-of-Life Options’, Sustainability, vol. 10, pp. 952–952, 2018, https://doi:10.3390/SU10040952.

Even More References

[6] A. Abdelshafy, A. Hermann, S. Herres‐Pawlis, and Grit Walther, ‘Opportunities and Challenges of Establishing a Regional Bio‐based Polylactic Acid Supply Chain’, Glob. Chall., vol. 7, 2023, https://doi:10.1002/gch2.202200218.

[7] Dattatray Bedade, C. Edson, and R. Gross, ‘Emergent Approaches to Efficient and Sustainable Polyhydroxyalkanoate Production’, Molecules, vol. 26, 2021, https://doi:10.3390/molecules26113463.

[8] N. Ehman and M. C. Area, ‘Bioplastics Are Revolutionizing the Packaging Industry’, Bioresources, vol. 16, pp. 4663–4666, 2021, https://bioresources.cnr.ncsu.edu/resources/bioplastics-are-revolutionizing-the-packaging-industry/

[9] Auxiliadora Prieto, ‘To be, or not to be biodegradable… that is the question for the bio‐based plastics’, Microb. Biotechnol., vol. 9, pp. 652–657, 2016, https://doi:10.1111/1751-7915.12393.

[10] Y. Tsang et al., ‘Production of bioplastic through food waste valorization.’, Environ. Int., vol. 127, pp. 625–644, 2019, doi: 10.1016/j.envint.2019.03.076.

[11] Kalim U. Shah and Isaiah Gangadeen, ‘Integrating bioplastics into the US plastics supply chain: towards a policy research agenda for the bioplastic transition’, Front. Environ. Sci., 2023, doi: 10.3389/fenvs.2023.1245846.

[12] N. Escobar, S. Haddad, J. Börner, and W. Britz, ‘Land use mediated GHG emissions and spillovers from increased consumption of bioplastics’, Environ. Res. Lett., vol. 13, 2018, https://doi:10.1088/1748-9326/aaeafb.

[13] ‘EU regrets inconclusive global plastics treaty – European Commission’. Accessed: Jan. 26, 2025. [Online]. Available: https://environment.ec.europa.eu/news/eu-regrets-inconclusive-global-plastics-treaty-2024-12-02_en