The challenge for recycling solar panels and wind turbines is growing quickly as Australia’s rooftop solar installations are the highest in the world (on a per capita basis). There are approximately 70 million (22.3GW) installed so far and research suggest there will be more than 1 million panels requiring replacement annually by 2031. With less than 2% of GDP to move the globe to net zero with both renewable energy and electric transport the demand for whole of life recycling is urgent.

A 2016 study jointly prepared by the International Renewable Energy Agency (IRENA) and the International Energy Agency (IEA) estimated around 250,000 tons of waste panels in 2016, but that would grow to 78 million tonnes of raw materials with a combined value of US$15 billion, and most of those could be recovered from solar panels globally by 2050.

IRENA estimated that global PV waste streams will grow from 250,000 tonnes in 2016 – or less than 1% of installed capacity – to more than five million tonnes by 2050. By then, the amount of PV waste will almost match the mass contained in new installations.

- High grade aluminium

- High grade silica dust

- The silica cells which will be reused by some manufacturers.

- Copper

- PVC

- Silver

Dead Solar Panels are the Hottest New Recylables

An article in Hackaday July 2022 spells out why recycling solar panels is a hot area.

- Current process is to grind them up, and use the crushed glass (glass cullet) but it costs $12 per panel and the panel is worth only $3

- FRELP process or “Full Recovery End of Life Photovoltaic” uses a hot knife to carefully separate out the silicon cells from the glass and plastic of the panel, which lets each component be processed separately. See Veolia below

Recycling Solar Panels

It has been hard to hit 100% recycling. In 2021, non-profit EU solar panel recycling body PV Cycle announced it had collected 5,000 tons of modules in France, of which 94.7% could be recycled. The proportion of materials potentially recoverable from solar panels is typically glass (75%), aluminium (8%), silicon (5%), copper (1%) and smaller amounts of silver, tin, lead and other components.

Back in 2015 Sustainability Victoria estimated that Australia’s installed solar infrastructure has a 15- to 35-year expected lifetime, so the waves of end-of-life panels are not expected to hit the dirt for another decade or so but the rapid rise of solar installations, a few floods fires and hail storms has brought the issue to the fore.

But Australia’s first working solar panel recycling plant Is up and running. The plant by Reclaim PC reportedly recycles 100% of end-of-life solar PV modules using no chemicals. Reclaim PV operates Australia’s leading end to end recycling and recovery network, allowing manufacturers, installers, retailers, site developers and other key stakeholders to significantly reduce the number of end-of-life solar panels and batteries going to landfill.

Additionally, reuse is very common, and household systems are completely replaced. The panels are then reused – either in Australia or shipped to other countries for us there.

Wind Turbines

Wind renewable energy has been growing exponentially with nearly 780GW deployed by end of 2020 and 850 GW by 2021 with over 381,000 turbines and rapidly growing. The average age was 20 years – but as wind turbine technology is improved, many companies will replace wind turbines before the end of life and install new ones. The cost of a farm includes site costs, roading, network infrastructure, and turbines, and a business case is often made to replace wind turbines to better utilise wind and location.

Germany and other countries with a high share of wind power are faced with the need to dismantle large quantities of wind turbines over the next decades and will have to come up with disposal and recycling systems and solutions at a large scale. For most of the turbines’ input materials, fairly well-established recycling procedures already exist. According to wind industry lobby group BWE, about 90 percent of an installation’s total weight could easily be fed into cycles for steel, metals and concrete.

The composite materials in rotor blades, however, are much more difficult to dispose of properly. Blades can also be dismounted and replaced, while the rest of the turbine stays in operation for repair or to increase the installation’s output. GRP blades often end up in landfill sites, are burned in waste incinerators or used as additives in concrete production.

Vestas has a Circularity Roadmap, and recycled their first 285 blades, and initiated the CETEC project to design the world’s first circular blade. By 2025 Vestas aims to have 100% recycling of wind turbines.

Breaking News – Vestas Recycling

In Feb 2023, Vestas claim their new process can recycle blades – even the ones previously sent to landfill (RenewEconomy) as they developed a new chemical process that is capable of breaking down epoxy resin into virgin-grade materials.

Recycling of Electric Vehicles

It is still early days for EV recycling although batteries are a key component. Redwood Materials is focused on batteries, but the aluminium from the frame, steel from the panels, copper from the motors and wiring, plastic from seats, linings and interior, materials from electronics, and the battery materials

Benchmark Mineral Intelligence, says even in the best run factories there is a scrappage rate of 10%. They predict by 2025 manufacturers could be making up to 800 GWh of batteries annually. If so, there could be as much as 80 GWh of scrappage a year — equal to total global battery production in 2016. And that’s before a single used EV or energy storage battery gets recycled. BMI forecasts the following amounts of raw materials being recaptured annually by 2025 with a market value of $1.5Billion

- 64,000 tons of lithium

- 96,000 tons of graphite

- 45,000 tons of nickel

- 18,000 tons of cobalt

- 22,000 tons of manganese

Recyling Solar Panels and Wind Turbines

| System | Country | Company | Notes | Links |

|---|---|---|---|---|

| Panels | Aust | Gedlec Technology | 100% panel recycle | Australia first 100% |

| Batteries | USA | Redmont Materials | Ex Tesla founder, funded by Ford, offtakes from Ford and Tesla, Raised $300m | Redmont Materials battery recycling |

| Panels | The Netherlands | Frauhhofer Institute | Fraunhofer ISE has developed a process for recycling the silicon in old solar panels | Cleantechnica article on process |

| Panels | Australia | Reclaim PV | Previously 10,000 panels per year, now 70,000 pa | Reclaim PV Website |

| Panels | Rousset, France | Veolia | Veolia 2,000 T in 2018, up to 5,000 T by 2020, all decommissioned PV panels in France | Veola news |

| Wind | Denmark | Vestas | consortium aims to commercialise within three years technology that can tackle thermoset composite bond | Zero Waste Turbines by 2040 |

| Wind Turbines | Spain & EU | various | The VIBES consortium, led by AITIIP (Spain), is comprised of 13 partners across 7 EU member states (Spain, France, Ireland, Germany, Belgium, Italy, Greece): 3 Research & Technology Organisations and 1 University (AITIIP, LEITAT, DITF, University of Limerick), 7 Small and Medium Enterprises (Specific Polymers, BCIRCULAR, FLIPS & DOBBELS, IDEC, Juno Composites, ARCHA, Q-PLAN International), 1 Large Company (ACCIONA Construccion), and 1 Public Body (Teruel International Airport PLATA) | European project for thermoset composites’ end-of-lifefor resin |

| Batteries | Australia | ABRI | The Australian Battery Recycling initiative is recycling companies to get lead, cadmium, mercury, lithium, uranium, manganese, nickel and zinc from batteries and as these materials are all non-renewable, can be recycled an indefinite number of times and have a commercial value. | includes domestic AA, electronics and vehicles |

| Batteries | Australia | B-Cycle | B-cycle's has convinced major companies including Eveready and Energizer to contribute 2 cents for every 24 grams of product they sell in Australia | Report on household battery recycling |

Images of Recycling Solar Panels and Wind Turbines

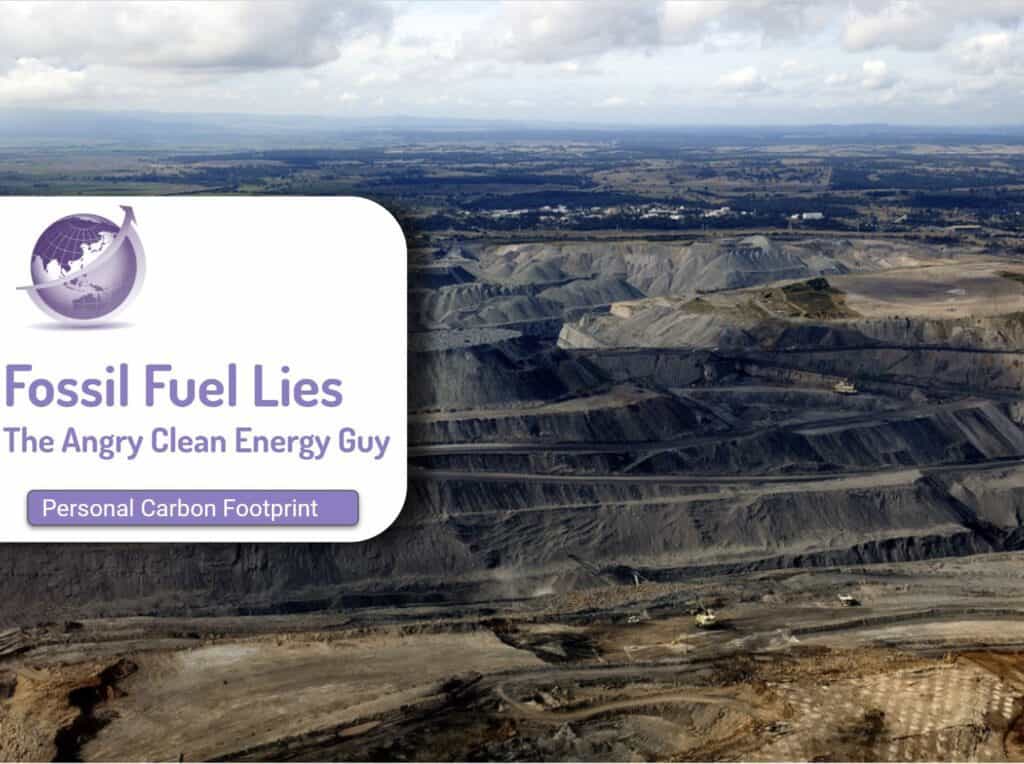

These are the types of images that fire up anti-renewable energy discussion.